As part of Trailer Safety Week, the National Association of Trailer Manufacturers (NATM) is continuing its mission to improve the safety of the nation’s roadways through education. One of the most common — and easily preventable — trailer safety issues is improperly torqued lug nuts. Whether you're a trailer owner, dealer, or manufacturer, understanding and applying proper torque is critical to avoiding wheel separations, equipment damage, and dangerous driving conditions.

Why Torque Matters

When it comes to your trailer’s wheels, torque is everything. Torque is the force that secures the lug nuts to the wheel studs, keeping the wheel attached to the hub. If lug nuts are under-tightened, the wheel can loosen over time, leading to vibrations, wear, or even complete wheel detachment — a frightening and hazardous situation for any road user. On the flip side, over-tightening can stretch the wheel studs beyond their yield point, weakening their structural integrity and increasing the risk of failure. Either scenario can lead to serious damage and danger on the road.

Understanding Torque

Torque is a measure of rotational force — how much force is applied to turn something — and in this context, it refers to the tightness of a fastener, typically measured in pound-feet (lb-ft). Achieving the correct torque ensures that the clamping force is strong enough to secure components without overloading or distorting them.

Over-Torquing vs. Under-Torquing: What’s the Risk?

Over-torquing can damage wheel studs, deform brake drums, or warp mounting surfaces. Once a stud has been stretched past its elastic limit, it no longer has the tensile strength needed to retain the wheel, increasing the likelihood of shearing under load. Conversely, under-torquing leaves lug nuts too loose, allowing vibration and movement between the wheel and hub. This can elongate holes, crack components, or even cause the wheel to separate completely — a serious hazard at highway speeds.

Studs not torqued properly on an aluminum wheel. (Photo Credit: The Trailer Guy)

Studs not torqued properly on an aluminum wheel. (Photo Credit: The Trailer Guy)

Studs not torqued properly on an aluminum wheel. (Photo Credit: The Trailer Guy)

Read our step-by-step guide on how to properly torque your trailer wheels → Here

Where to Find the Right Torque Specs

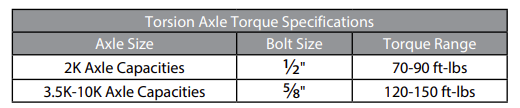

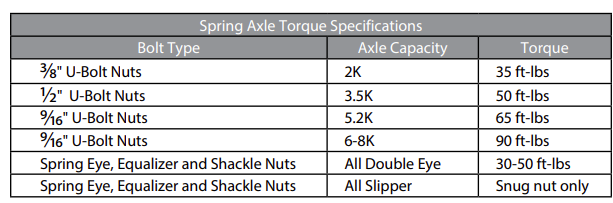

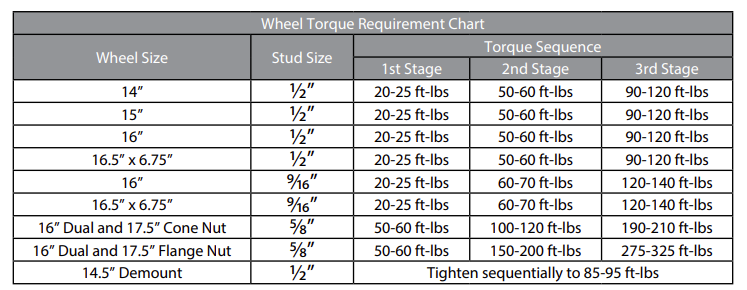

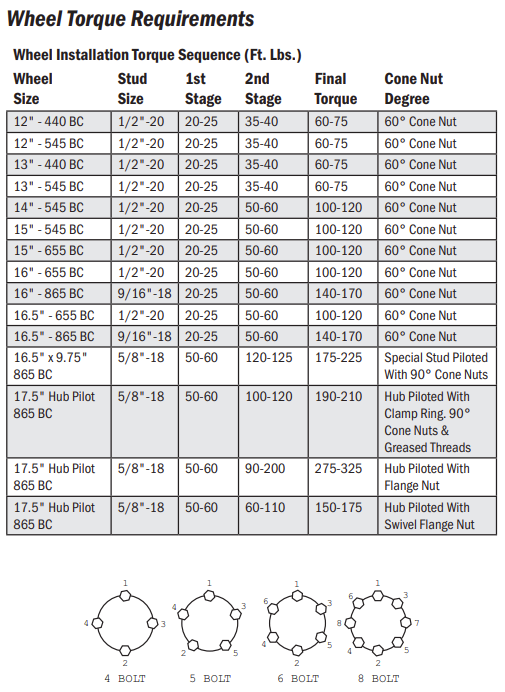

So how much torque is the right amount? The answer depends on your trailer’s axle type and rating. Torque specifications are typically listed in your trailer owner’s manual, axle manufacturer documentation, or the component manufacturer's website. For your convenience, we’ve included torque specification charts from leading axle manufacturers Lippert and Dexter to help guide you.

Note: Always verify torque values with your axle manufacturer, as the specifications can vary. The values provided are general ranges. You can typically find a decal or label on the axle with manufacturing details to help identify the correct specifications.

Photo Credit: Lippert

Photo Credit: Lippert

Why Torque Settings Vary

Not all axles are created equal. Torque requirements vary based on axle capacity, hub type, wheel material, and fastener specifications. Higher-rated axles require more clamping force, which means higher torque values. Similarly, the type of wheel (steel vs. aluminum) can affect the recommended torque due to differences in material hardness and thermal expansion. This is why referencing manufacturer-specific data is essential — generic values may not apply to your setup.

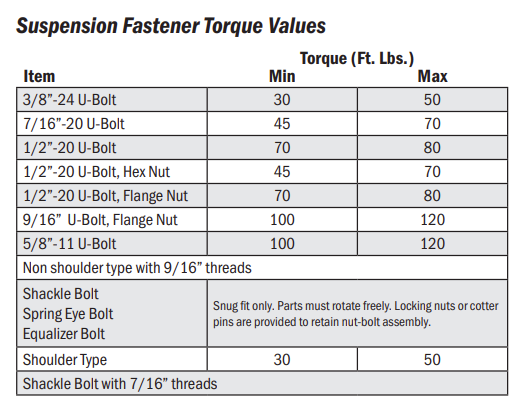

Don’t Forget the Suspension: U-Bolts & Fasteners

While lug nuts get a lot of attention, don’t overlook your suspension components. U-bolts, shackle bolts, and other suspension fasteners also require proper torque. Under-torqued suspension bolts can lead to axle misalignment, uneven tire wear, and compromised handling, while over-torquing can crush bushings or bend components. We’ve included a helpful chart from Dexter that outlines suspension fastener torque values by size and application.

Photo Credit: Dexter

Lug nuts improperly installed. (Photo Credit: The Trailer Guy)

Stud Size Matters

The diameter and thread pitch of wheel studs directly impact how much torque they can safely handle. For example, a 1/2" stud will have a different torque range than a 9/16" or 5/8" stud. Applying the wrong torque to the wrong stud size can result in failure or unsafe conditions. We’ve included a torque chart by stud size for reference, but remember — always follow your manufacturer’s recommendations. Torque values should never be guessed.

Pro Tip: Always install conical lug nuts cone side toward the wheel. This helps center the wheel on the hub and ensures even clamping force across the contact surface.

Photo Credit: Lippert

Photo Credit: Dexter

New Trailer? Double Check Your Torque

Brand-new trailers require special attention. As you drive, lug nuts and wheel studs may seat and stretch slightly, altering the initial torque. That’s why it’s vital to re-torque wheels after the first 10, 25, and 50 miles — or as your manufacturer recommends. If you’re unsure how to check this yourself, visit an NATM-affiliated dealer or service provider for professional assistance.

Stay Safe and Secure

Proper torque is more than a number — it’s a commitment to safety. Whether you're hauling for work or recreation, keeping your trailer's wheels and components securely fastened protects not just your cargo, but everyone on the road. Take the time to double-check torque specs, use the right tools, and consult your manufacturer’s handbook. A few extra minutes in the driveway can prevent disaster on the highway.

While it's tempting to opt for a heavy-duty hitch for towing purposes, many overlook the importance of matching the hitch to the tow vehicle's specifications. This oversight can lead to serious safety hazards on the road.